BOLTS

A bolt is a type of threaded hardware fastener that is used to position two workpieces in specific relation to each other. Bolts come in several configurations for their application and specification variances.

Since the terms "bolt" and "screw" were in use before the advent of easily-produced helix fasteners, they are often synonymous.

Bolt Dimensions

The dimensions of a bolt can be expressed in metric or imperial units, both of which are better explained in the Bolt Standards section of this selection guide.

- Pitch is the measurement between the apex of adjacent threads on the bolt's shank.

- Diameter is the width of the screw shank. This should not include the bolt head.

- Length is the measurement of the bolt from the edge of the chamfer to the undercut of the head. Against this measurement should not include the head.

Bolt Material

- Aluminum screws are light, resistant to oxidation, thermal and electrical conducive, and easy to manufacture.

- Brass screws are strong, conductive, and corrosion resistant, with low magnetic permeability.

- Copper alloy screws have good load capacity, wear resistance, and are suitable for use near magnets.

- Plastic screws are inexpensive and corrosion resistant for light loads. They are common for applications near water, such as pools.

- Steel screws are produced of strong, carbonated iron. Uncoated steel is vulnerable to corrosion.

- Hardened steel screws are stronger than steel screws, but more brittle. They are made of steel treated by tempering and quenching methods.

- Stainless steel screws are chemical and corrosion resistant with an appealing finish. They cannot be hardened like carbon steel.

- Screws consisting of superalloys exhibit good mechanical strength, surface stability, corrosion resistance, and resistant to creep at high temperatures. Common super alloys include Hastelloy®, Inconel®, Incoloy®, and Monel®.

- Titanium screws are hard and strong, light, and corrosion resistant. When alloyed with other metals, it increases strength and durability.

Bolt Production

Bolt Operation

The components that form a bolt can be identified in three sections. The head is the part of the bolt with the largest diameter, which provides a mount for tools to either apply or resist torque. It also provides part of the bearing surface for substrates being bolted. The shank of the bolt is the longest part of the bolt and has external, helical threads on its circumference. This piece is responsible for the alignment of the workpieces. Finally, the end opposite of the head is known as the chamfer, which provides a slightly beveled edge to aid the bolt's insertion into holes and nuts.

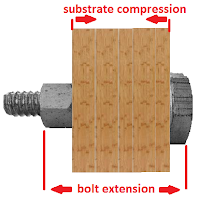

Successful bolt implementation almost always requires a nut to retain components on the bolt's axis. Nuts are applied via torque while the bolt itself is held in place, or vice versa. Nut position and bolt employment are dependent upon the same physical principles: the friction of the bolt and nut threads against one another, which is comprised of a slight stretch of the bolt from the compression resistance of the components being fastened, and a slight elastic deformation of the parts held together.